Data! Measuring data has never been easier in cultivation. Precision air, lighting, and nutrient recipes are ready for any sensor to sample, report, and store for immediate visualization or future analysis. Mesh networks, self-aware microcontrollers, and rulesets are ready to act as artificial intelligence to minimize the distance from theory to execution and capture what was done to get there. Let’s talk about a few examples.

AEssenseGrows provides software-controlled precision systems for grow operations. One of our customers, 420Kingdom, uses AEtrium System aeroponics to deliver amazing results with >40% cannabinoid bundles and >35% THC. How do they achieve this level of performance?

Precision Sensors

For the perfect environment, operators need to measure room temperature with lights ON and OFF, but not just the air temperature (68-75°F), humidity (starting at 90% ramping down to 45%), and carbon dioxide (CO2) content (1500 ppm). They also need to measure, monitor, and action water temperature (60-70°F), chilling, and adjustments for light intensity (700-1200 PPFD, photosynthetic photon flux density) and frequency based on where they are in the grow cycle. They need to manage dehumidifiers, CO2 burners/injection, and air mixing/fan speeds. Precise nutrient salt dosage needs detailed adjustments for ratios, mix, and irrigation timing.

All of these variables can be very regimented and held to a specific range of value, timing, execution, and sampling. The guide map or “grow recipe” is an adjustable template to be tested and refined with steady innovation. The bottom-line enhancing reward for this effort is continuous learning, yield improvement, and higher profitability.

Historic cultivation developments were gut-feel and experience based in the grey market. “I’ve been doing this for 20 years,” is often the way this conversation starts. This was sufficient when the competition was limited and annual grow cycles were state-of-the-art. But today, indoor controlled environment cultivation is being driven year-round by major corporations investing millions of dollars in research and data-driven scientific methods to guarantee their investments. Fighting fire with fire is the only way to stay ahead of these behemoths.

At AEssenseGrows, we use a “Fire, Ready, Aim” data driven philosophy to drive continuous improvement and innovation.

Fire, Ready, Aim?

Fire (or shoot at the target) begins with the best data collection and execution engine you can get. There are alternative, build-your-own approaches, but in our case, AEssenseGrows offers precision sensor based modular aeroponic turn-key systems. Plug in water and power, and start your first grow operation with effectively infinite oxygen in the root zones of your cultivars (aeroponics inherent benefit).

Start with a recommended grow recipe or dial-in your own nutritional recipe, irrigate on a schedule that never gets tired, add light intensity and timing for what is day and what is night, set the environmental targets, humidity, and airflows, and you can deliver solid yields out-of-the-box.

But guess what? Every cultivar, environment, and situation is different. The first “shot” is far from perfect, and this is where practice, trials, and data come in.

“Ready”: Precision, Consistency, Data

Ready means gathering data from all of the systems in the environment. “MEP” (mechanical, electrical, and plumbing) resource design is critical to your grow environment. Operators need to be able to monitor, perform actions, sample, and track air, water, and electricity at all times. HVAC (heating, ventilation, & air conditioning) is another critical aspect for monitoring, control, and modification of the air in your environment. Keeping your temperature, humidity, and air-flow moving (or well mixed) provides plants with consistent critical resources to optimize photosynthesis. Gaps in any of these resources can stop progress immediately.

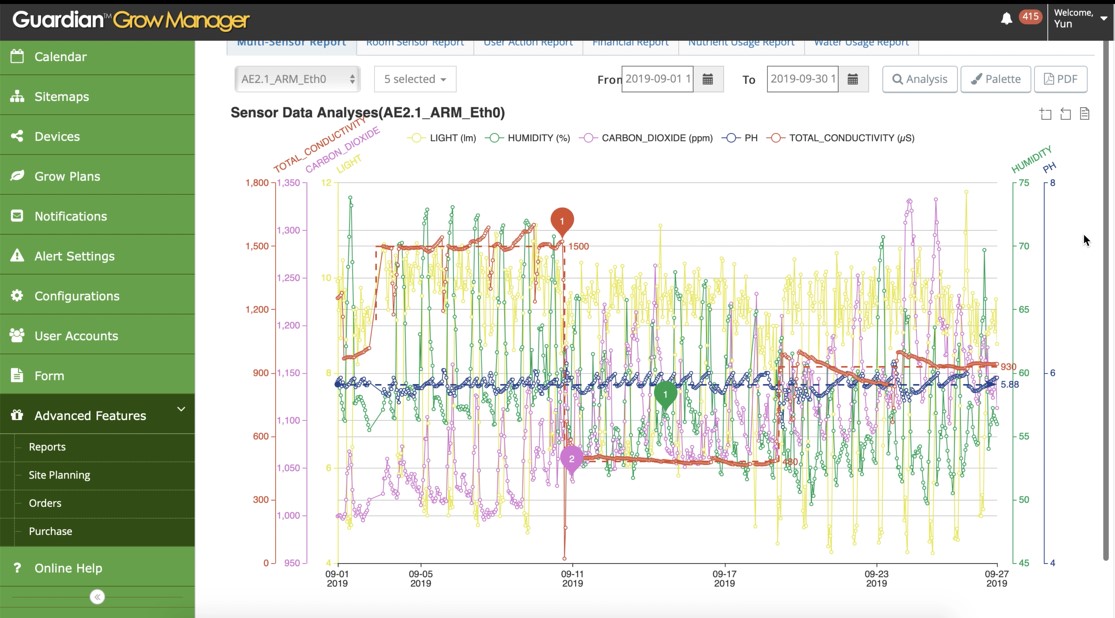

A professional central control system like the Guardian Grow Manager from AEssenseGrows collects data from precision sensors at all of these data points and monitors every facet of a grow operation, and that leads us to “Aim.”

Aim describes the direct control adjustments made to the entire grow plan and cycle to improve performance. Aggregating the process for the big picture with data visualizations is a good start. This makes it easier to understand an entire operation. Adding the ability to drill into any detail of a grow plan is highly valuable (nutrition, irrigation timing, temperature, air-flow, pH, CO2, humidity, light intensity/schedules, location, machine, or plant). What effect do different environmental controls have on your results? Data access and your ability to compare grow results side-by-side provides decision inputs for continuous improvement.

“Fire, Ready, Aim” is the process of gathering, analyzing, and acting on your side-by-side experiments with single variable A/B profiles. Evaluate your results and then move on to the next precision experiment. Create and test your environment parameter by parameter.

Discovery, Trials, “Fire, Ready, Aim” Innovation

Precision software control enables you to design the environmental parameters to drive flower size, yield, terpenes, flavor, color, and/or cannabidiol/tetrahydrocannabinol (THC) profiles for your genetics.

Redefine The Market: Breakthroughs.

A final innovation I will cover is from an advanced company located in South Africa called FarmaGrowers. This past August, using our aeroponics platform, they delivered the first fully certified GMP and GACP high-THC bud from South Africa to medicinal cannabis suppliers in Australia. This was the first product to pass the stringent import requirements of the Australian government agencies. They followed this achievement quickly with successful imports into Germany. You can read their announcement here.

Precision data collection and monitoring enables companies to be bold, try new things, and approach new markets. Fire, Ready, Aim innovation offers data to enable breakthrough ideas that may not be obvious at first glance. Specialty flower, colors, shapes, smells, or terpenes can be pushed in new directions and be highly profitable in high density, indoor environments (cannabis is far from the only example). Saffron, wasabi, herbs, and specialty medicines offer great potentials if one gathers their data and “fires” away.