COMERGTM who owns the worldwide IP and know-how of the R134a extraction technology is proud to announce the new cultivar specific terpene rich product lines delivered by utilizing the PURE5TM equipment extracting high quality flowers.

PURE5TM Extraction is introducing a line of Pure Botanical Extracts (PBXTM) Full Spectrum Hemp Terpenes delivered from fresh flowers preserving the natural terpenes from the original hemp cultivar.

“Our Hemp Terpenes are produced using a non-destructive, pure botanical extraction process that concentrates all the terpenes in an unaltered profile suspended in natural oils from the plants.”, said the CEO of COMERG Dr. George Stantchev.

For this product PURE5TM selects the highest quality hemp or cannabis flowers coupled with Pure Botanical Extraction (PBXTM) process delivering the highest concentration of terpenes. The cultivars are uniquely grown to boost the full terpene spectrum in the flower, then selectively extracted to bring nothing but the pure natural terpenes including all major and minor terpenes. Our extraction process employs a low-pressure, room-temperature, non-polar fluorocarbon solvent allowing us to capture every potential terpene along with elemenes & ketones all suspended in the natural oils from the hemp flowers.

Flower terpene profile

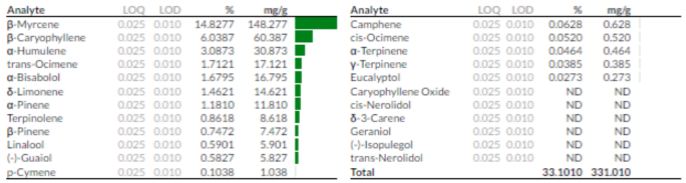

Extract Terpene Profile

What is unique here, is that the extracted terpene profile repeats the exact flower terpene profile in approximately 30 times more concentrated form. The additional two terpene profiles detected in the oil were below the detection threshold in the flower and were detected in the extract after they have been concentrated. Since the extraction is carried out at room temperature there is no destruction of existing terpenes or new by-products created in the process. That means that the experience of using the flower in any delivery form either vape, supplement or topical will be exactly as the plant itself maintaining the terpene, enzymatic and mineral content intact.

PBXTM terpene oils can be added to all hemp derivative products to enhance flavor, ensemble effects, and vape oils.

Utilizing PBXTM extraction methodology and employing Low Pressure / Room Temperature extraction delivers fully vital and natural components of the original hemp plant. Our terpene extraction is supplied with a chain of custody all the way back to the original flower cultivar. Incorporating PBXTM terpenes into your formulation brings your CBD/THC products to another level of quality by getting closer to the original and fully vital flower form.

Most botanically sourced terpenes are extremely concentrated; however, they may be suspended in alcohol. The alcohol, therefore, must be employed in your formulations regardless of the solvents present. PBXTM delivers all the components of the flower we want and none of the by-products that other, widely used solvents will create due their aggressive nature.

Our terpene fraction captures the entire terpene profile from the plant in highly concentrated oils. PBXTM Terpenes are the perfect companion to our full spectrum hemp oils, which is the follow-on fractionation concentrating the entire cannabinoid profile over 65% with a lower concentration of terpene oil.

All our products are third-party tested for cannabinoids, terpenes, residual solvents, inhalable microbial contamination and the presence of pesticides.

Myrcene, caryophyllene, humulene, pinene, and linalool are more common amongst hemp flowers, however, the quantity present in Lifter makes this a very complex flower profile yielding superior ensemble effects.

Lifter Live Resin delivers:

- 33.1 % Concentration of Terpenes

- 34.12% Total Cannabinoids

- 28.4 % CBDa / 3.44% CBD

- Up to 40% Conc in finish products

This product is a full spectrum extract from registered hemp variety Lifter that was organically grown by Kind Roots Inc in Colorado and Oregon.

Who we are

PURE5 Extraction, powered by COMERG, designs and manufactures cost- and process-optimized extraction systems and applicable post-processing stages targeting specific end products. COMERG is committed to offer the fastest, safest, and most economical extraction process for cannabidiol- or tetrahydrocannabinol-rich oils named Pure Botanical Extraction (PBXTM) standard.

COMERG originates from building machines for fragrance and flavor production in Europe. This technology by itself and combined with ethanol has been used to extract various herbs. Based on that vast experience, COMERG developed various levels of equipment by processing capacity.

TF2L010AU Lab unit

The fully automated TF2L010AU machine processes 40 lb of material a day. It consumes 2 kW of power on average and does not requiring expert installation and operation. It provides, on average, around 1-2 kg extract a day that can be directly infused in a product. It has been widely used by the industry for direct formulations.

TF2L100AU Extraction area

The TF2L100AU machine extractors are installed separately from the skid. The loading and unloading is done by vacuuming the material and collecting it in the cyclone in order to maintain low dust levels. While this machine supports high production loads, it is extremely easy to operate and maintain.

Extractors are manufactured with 304 stainless steel with volume of 100L that can accommodate 15-20 kg raw material. The space needed for installation is approximately 50 m2. Extractors are equipped with agitators and a vacuum system for load and offload. Extractors can be serviced through a bay flange. System is fully automated, remote-controlled, and installed as a full turnkey system, loaded with solvent.

TF2L100AU Clean Room area

The fully automated TF2L100AU machine processes 600 lb of material a day. The TF2L100AU consumes 25 kW of power, on average, and is installed as a turnkey system with closed-loop solvent recovery. The system does not require expert operation and provides, on average, around 20-30 kg of extract a day that can be used directly in a product. This GMP compliant system has been widely used by the medical cannabis and hemp industries for single-pass processing.

Typical Install in GMP facility

The TF2L250AU and TF2L500AU models are upscaled versions of the TF2L100AU. They process 2,000 and 4,000 lbs of material per day, respectively. The systems are modular and can easily scale up to cover dynamically changing processing loads.

The fully automated, GMP compliant TE1L1000AU dual solvent system processes 2,000-4,000 lb of material a day. Consuming 45kW of power, on average, the TE1L1000AU is installed as a turnkey system with closed-loop dual solvent recovery and doesn’t require expert operation. This system provides, on average, around 100-200 kg extract a day that can be used straight in a product.

PURE5 powered by COMERG is an industry leader with the first single pass resin extraction technology with easy scalability and high safety rating. PURE5 brings proven, scalable equipment, technological advances and years of acquired knowledge to any commercial processor, no matter the size of their operation.

###

For inquiries contact:

Dr. George Stantchev, CEO

george@comerg.com

(602) 992-0744